Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Type 11 WN

Brand: NC

Place Of Origin: China

Standard: Ansi, Bs, Din, Gb, Iso, Jis, Jpi, Asme

Packaging: Plywood Case

Productivity: 12000ton/year

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 12000ton/year

Certificate: ISO9001:2015

HS Code: 73079100

Port: Tianjin,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF

Welding neck flange is the correct terminology to be used as standards. However in the industry Welding Neck Flanges are commonly refered to as Weld Neck Flange. The welding neck flange consists of a tapered hub which is secured to the pipe by a full penetration butt weld. Because of the additional reinforcement area avaliable in the hub of weld neck flange and due to its installation by welding, the hub becomes an integral part of the pipe. This gives a weld neck flange greater strength and integrity and ability to withstand considerably higher bending moments than a slip on flange. Since welding neck flanges are secured to pipe by butt welding, the internal diameter of the hub end should match the interal diameter of the pipe end. The details of matching pipe ID or Wall thickness are required to be specified for purchasing weld neck flanges. The advantage of welding neck flange is the butt weld permits non-destructive examination by radiography to be carried out on the weld neck flange unlike slip on flange which can be examined only by magnetic particle inspection or dye penetration inspection. The weld neck flange can be directly welded to butt weld fittings like elbows, tees, or reducers without requiring any short piece unlike slip on flange which requireing any short piece of pipe unlike slip on flange which require a straight length of pipe for installation. Despite the initial procurement cost of weld neck flange being higher than a slip on flange, the installation cost (which includes welding and inspection) reduces the differential. Welding neck flanges can withstand higher bending moments. Welding neck flanges are suitable for piping systems subject to high pressures, high cyclical loading, high temperatures as well as cryogenic services.

The industrial processes come into die forging,and machining,we can provide a wide range of flanges,following on standards like ASME B16.5 Flange , ASME B16.47 Flange, DIN 2573 Slip On Flange, DIN 2631 Welding Neck flange, JIS Flange 5K SOP Flange and JIS Flange 10K SOH Flange. ASME Flange include ASME B16.5 Flange, ASME B16.47-A Flange, ASME B16.47-B Flange, this standard system include slip on flange, blind flange, welded neck flange, Threaded Flange, lapped joint flange (loose flange), socket welded flange, B16.36 Orifice Flange, long weld neck flange and Special Flange, sizes from 1/2 inch to 60 inch, class 150, class 300, class 600, class 900, class 1500, class 2500.

Product Categories : EN1092 Flange > Type 11 Flange

New Century Forging Co., Ltd, established in 2002, is a professional flange manufacturer in China, producing forged flanges and various forgings parts in the material of stainless steel, carbon steel and alloy steel, etc..

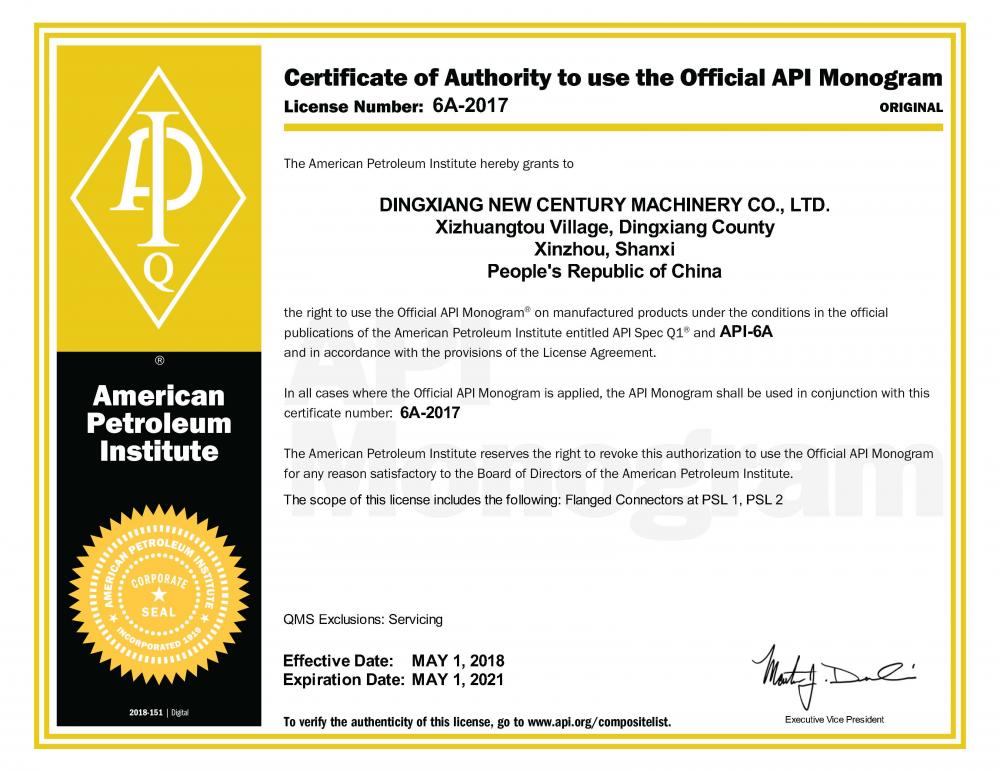

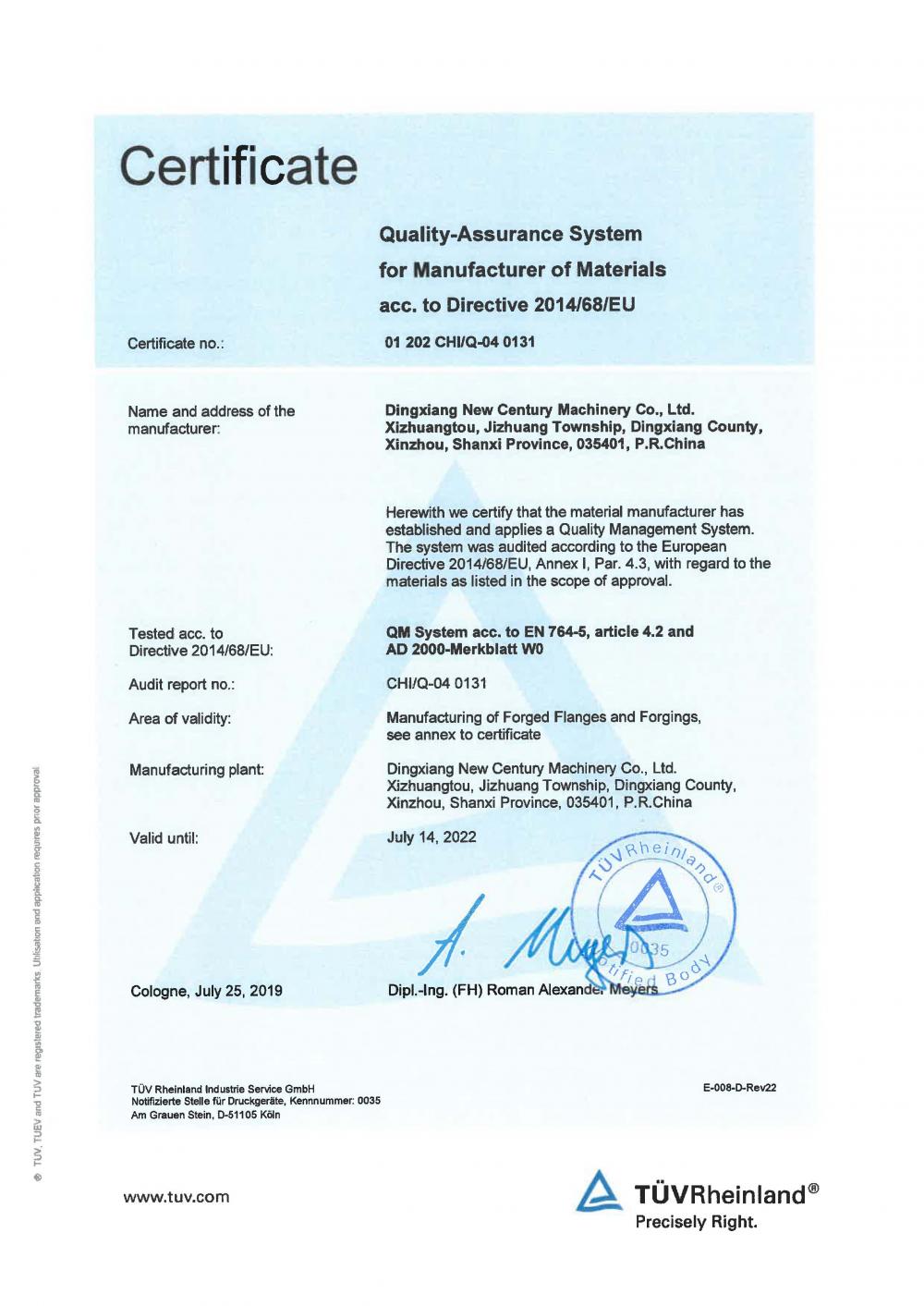

With 18 years’ development, we are now having 260 employees and 55,000 square meters working area. There are over 200 sets of forging and machining facilities in our factory for production, including 21 sets of CNC blanking machine, 8 sets of air hammer machine, 5 sets of ring rolling machine, 2 sets of rod-clamping hammers, 2 sets of screw press, 60 machining lathes, 40 CNC machining lathes, 24 CNC hole drilling lathes (10 high-speed CNC hole drilling lathes). Besides, our complete set of product testing equipment guarantees us to provide good and qualified products to our clients and potential customers, such as Brinell hardness tester, photoelectric direct reading spectrometer, microcomputer automatic heat metering instrument, impact tester, ultrasonic flaw detector, portable spectral analyzer and universal testing machine, etc. We have obtained certificates ISO 9001, TUV/PED, API, CRN, etc.

The annual production capacity of our factory reaches 20,000 tons. We provide flanges with sizes from 1/2" to 170". Flanges are produced with the quality up to the standards ASME B16.5, B16.47, AWWA, DIN, BS, KS, JIS, EN1092-1, AS2129, etc.. Besides standard products, we also manufacture various kinds of specially designed flanges and forging parts according to customer's drawings or samples.

Mainly of our products are exported to more than 30 countries, such as Canada, South Korea, Japan, Italy, Turkey, Germany, America, Denmark, etc.. We enjoy a good reputation for our high quality, fair price and reliable after-service. We sincerely welcome clients to visit our company and cooperate with us. Any inquiries will be replied quickly and professionally.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.