Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DIN 2527

Brand: NC

Place Of Origin: China

Standard: Ansi, Bs, Din, Gb, Iso, Jis, Jpi, Asme

Packaging: Plywood Case

Productivity: 12000ton/year

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 12000ton/year

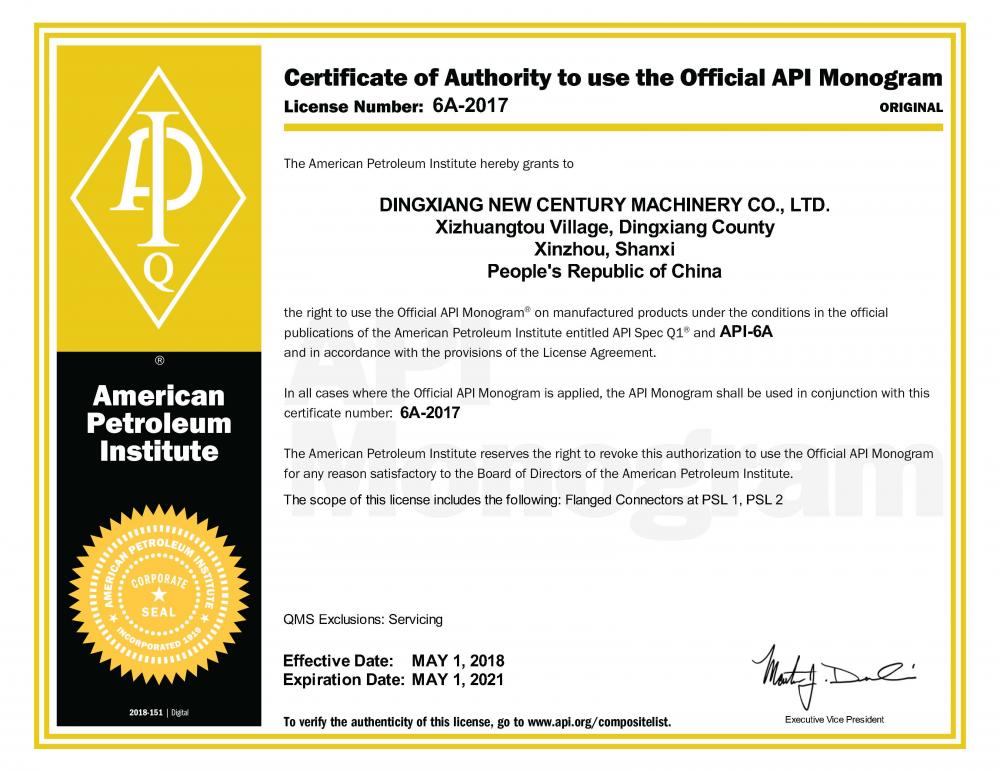

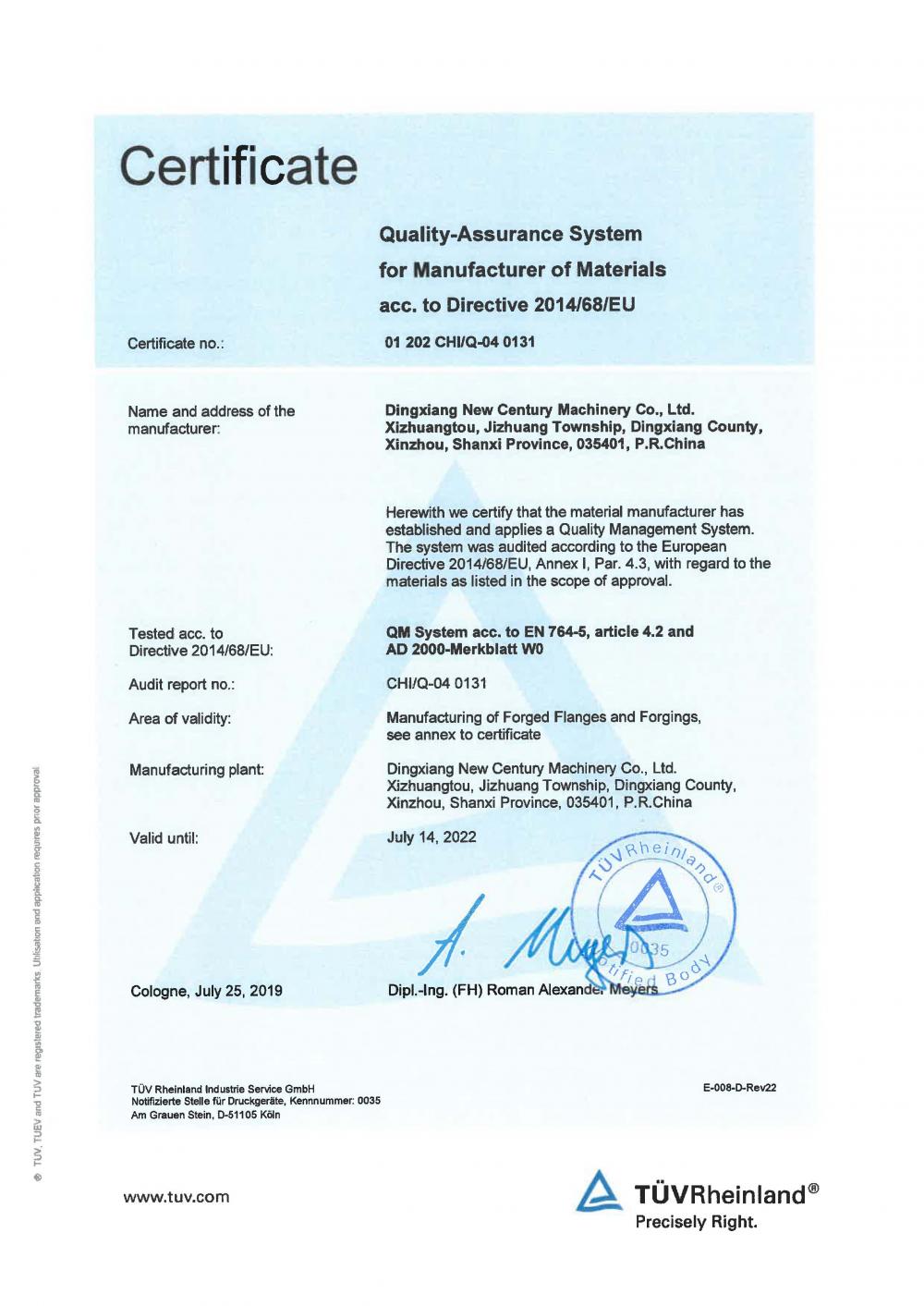

Certificate: ISO9001:2015

HS Code: 73079100

Port: Tianjin,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF

Blind flanges are used to blank off the ends of piping, valves and pressure vessel opening. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed of all flange types. Blind flange is also used in the flange of the import and export of the equipment, which is used to connect the two equipment. Blind flange is installed at the end of piping system either on a header or branch connection or on a valve and functions as a mean for positive isolation of the piping system. Piping headers can be terminated at the ends using a butt weld cap. However the cap is often substituted by a blind flange if a provision for future extension of the header is required. On drain systems blind flanges serve as important rodding points or can be dismantled for easy inspection. Blind flanges can be drilled and used as reducing slip on flanges or the blind flange can be drilled and tapped for use a threaded reducing flanges. Blind flanges are avaliable in the same pressure ratings as weld neck flanges and with various gasket facings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

The industrial processes come into die forging,and machining,we can provide a wide range of flanges,following on standards like ASME B16.5 Flange , ASME B16.47 Flange, DIN 2573 Slip On Flange, DIN 2631 Welding Neck flange, JIS Flange 5K SOP Flange and JIS Flange 10K SOH Flange. ASME Flange include ASME B16.5 Flange, ASME B16.47-A Flange, ASME B16.47-B Flange, this standard system include slip on flange, blind flange, welded neck flange, Threaded Flange, lapped joint flange (loose flange), socket welded flange, B16.36 Orifice Flange, long Weld Neck Flange and Special Flange, sizes from 1/2 inch to 60 inch, class 150, class 300, class 600, class 900, class 1500, class 2500.

Product Categories : DIN Flange > DIN 2527 Blind flange

New Century Forging Co., Ltd., established in 2002, is a professional manufacturer in producing forged flanges and forging parts.

After 18 years` development, we have 260 employees and 55,000 square meters in area, over 200 sets of equipment for forging and machining.

Product description as follows:

1. Manufacturing standards: ASME B16.5; B16.47A, B

2. Pressure rating: 150LB~2500LB;

3. Product material: F304, F316, carbon steel, alloy steel

4. Production process: blanking-forging-heat treatment-machining-surface treatment-plastic box packaging

5. Product features: high temperature resistance, long service life, smooth surface, beautiful appearance, quality assurance

6. Scope of application: chemical industry, offshore petroleum, electric power, water supply, shipbuilding, nuclear energy, biopharmaceuticals, papermaking, boilers, construction, solar energy, heat treatment, etc.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.